-

Direction

• Basic research in micro and nano-machining mechanics and technologies

• Development of advanced processes and technologies in ultra-precision machining

• Energy efficient lighting technology based on freeform optics

• Advanced optics in aeronautics, illumination and imaging technologies

• Multi-functional and bionic structured surfaces

• Development of facilities, equipment and standards in ultra-precision machining and freeform surface metrology

• Nano-Freeform Technology for Biomedical Applications -

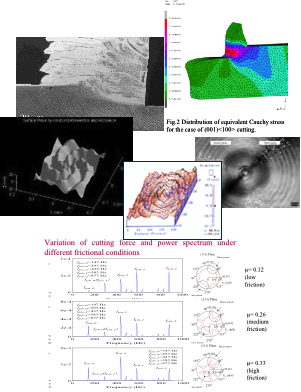

Basic research in Micro and Nano-machining Mechanics and Technologies

微納米加工理論的基礎性研究

• Modeling the Size Effect in Ultra-precision Machining by Multi-scale Plasticity Approach

• Modeling and simulation of Surface Generation in ultra-precision machining

• Ultra-precision diamond turning of difficult -to-machine ferrous alloys

• Stress Induced Microstructural Changes in the Ultra-precision Machining of Heat-treatable alloys -

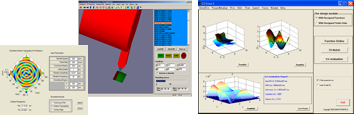

Development of Advanced Processes and Technologies in ultra-precision machining

開發超精密加工的先進工藝及技術 • Tool Path Generator for Optical Freeform Surface Machining

• Tool Path Generator for Optical Freeform Surface Machining

• Ultra-precision Freeform Surface Measurement and Evaluation

• Characterization of Optical Microstructures Using Pattern and Feature Parametric Analysis

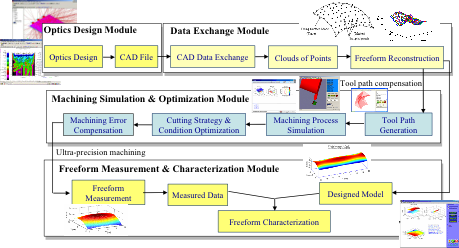

• Development of an Integrated Platform for Optics Design, Machining and Measurement of Optical Freeform Surfaces

(自由曲面光学设计,加工,测试一体化的集成平台 )Technological advancement 技術的創新性

• The integrated system is the first of its kind in mainland China and overseas for the design and manufacture of free-form optical surfaces, without the need to rely on the import of technology from overseas.

• The achievements are able to meet international standards. In comparison with related technologies developed in the local area or in overseas countries, the research team is in the leading position in this research area.Advantages of the Integrated System 集成平台的優勢

• It is capable of predicting the performance of the machining process and optimizing the cutting strategy. This minimizes the need for expensive trial cutting tests. The machining time can be reduced from more than 10 days to several days.

• With the development of the automated freeform tool path generator, the time required to program the machine tool path is significantly reduced.

• Reduction of tool wear

• The system is equipped with a series of algorithms which allow the measurement of optical freeform surfaces. This helps to improve the surface quality of the products.

• A framework of Surface Intrinsic Feature (SIF)-based Freeform Surface Characterization System is also proposed which thought some light for the future development of generalized and standard freeform surface algorithm.

• It is capable of predicting the performance of the machining process and optimizing the cutting strategy. This minimizes the need for expensive trial cutting tests. The machining time can be reduced from more than 10 days to several days.

• With the development of the automated freeform tool path generator, the time required to program the machine tool path is significantly reduced.

• Reduction of tool wear

• The system is equipped with a series of algorithms which allow the measurement of optical freeform surfaces. This helps to improve the surface quality of the products.

• A framework of Surface Intrinsic Feature (SIF)-based Freeform Surface Characterization System is also proposed which thought some light for the future development of generalized and standard freeform surface algorithm.

-

Development of Secondary Freeform Optics for Energy Saving

基於自由曲面光學的高能效照明技術• Development of advanced freeform secondary optics for LED road lamp and LED automotive lighting,. The optics can enhance the efficiency of the lighting systems, increase the uniformity of light distribution • Development of secondary optics to effectively collect the solar power so as to miniaturize the solar energy systems and reduce the use of solar panel • Complex optical systems for exploiting solar energy by collecting and channeling sunlight for interior illumination of buildings

-

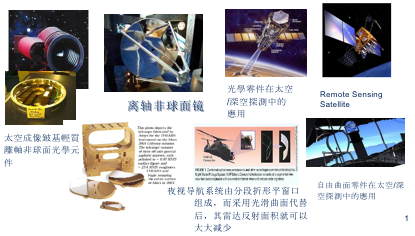

Advanced Optics in Aeronautics and Astronautics

用於航太、照明及成像等領域的先進光學超精密加工技術

-

Nano-Freeform Technology for Biomedical Applications

用於生物醫學應用納米自由曲面技術To provide a test bed for industry for a new generation of ultra-precision free-from products for bio-medical applications such as in orthopaedic implants Cells of tissue in their native microenvironment interact with three-dimensional (3D) nano-structures. The development of the ultra-precision freeform machining technology for fabricating bio-degradable substrates with 3D micro/nano-structural features to manage the growth of tissue

-

Research on Multi-Functional Bionic Nanostructures

多功能和仿生結構性曲面• Shark skin to manage the flow of liquid. For example, shark skin structure can reduce friction in water and drag reduction for other technical applications, e.g. high-efficiency heat exchanging copper tube. • Lotus leaf and butterfly wings which possess the specific structure giving them superhydrophobicity or self-cleaning properties. • Compound eyes from insects which show excellent visual acquisition with possible future applications in high-speed motion detection and sensors in different areas

-

Development of Equipment/Facilities for Ultra-Precision Machining and Metrology

開發超精密加工和自由曲面測量方面的設施、設備及標準• To develop of ultra-precision machining and nano-surface metrology equipment for freeform surface characterization. The ultra-precision machines made in mainland China have shown some progress in recent years. However, a technological gap still exists as compared with the state-of-the-art technology in terms of form accuracy control and other aspects. • To work closely with various international bodies (EUSPEN, ASPEN, ASPE, JSPE) to develop international standards for free-from nano-metrology and promote international collaboration in UPMT

Main Research area